Choosing the right concrete flooring option for your manufacturing facility is important. Furthermore, you want a durable floor that can withstand the heavy traffic of machines and people. So, you look for a variety of options that will protect your floor.

When you’re looking to install a new floor in a manufacturing facility, there are a lot of factors to consider. The type of flooring that you choose will have a big impact on the safety and efficiency of your workplace.

This blog post will look at some concrete flooring options for a manufacturing facility. We’ll also discuss the benefits of each option and how to choose the right one for your business. Please, continue reading for more information on some of the most popular flooring options.

Factors to Consider in Choosing a Flooring

There are several important factors to consider when choosing flooring for a manufacturing facility. First, the flooring must be able to withstand heavy foot traffic and the weight of machinery. Second, it should be easy to clean and maintain, as a manufacturing environment can be quite messy. Third, the flooring should be slip-resistant to prevent accidents.

With these factors in mind, tile is often a popular choice for manufacturing floors. Moreover, tile is durable and easy to clean, and it comes in a variety of slip-resistant finishes. However, tile can be quite hard on the feet, so it is important to choose a finish that is not too abrasive.

Another popular option for manufacturing floors is epoxy. Furthermore, epoxy is durable, easy to clean, and customizable to provide traction. However, epoxy is susceptible to high temperatures and chemical spills, so it may not be the best choice for all manufacturing environments.

Ultimately, the best flooring option for a manufacturing facility will vary depending on the specific needs of the business.

Tile Flooring

There are a few things to consider before deciding if tile flooring is the right choice for your manufacturing facility. On the plus side, tile is easy to clean and maintain, and it stands up well to heavy traffic. It’s also slip-resistant, which is important in a manufacturing setting.

On the downside, tile can be hard on feet and back, and it may not be the best choice for areas with high humidity or exposure to chemicals. Ultimately, whether or not tile flooring in your manufacturing facility will come down to weighing the pros and cons based on your specific needs.

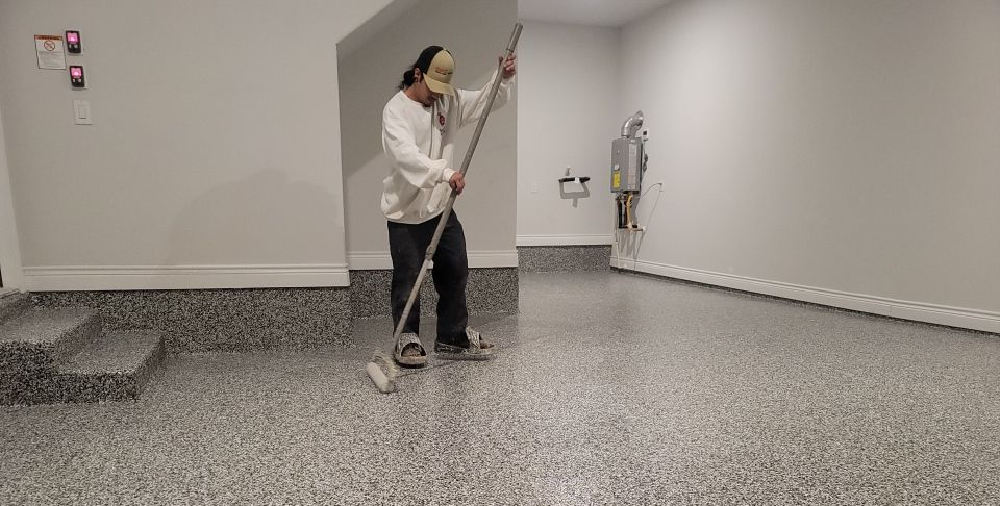

Epoxy Flooring

Epoxy flooring is a type of flooring that consists of a layer of epoxy resin, which mixes with a layer of polyurethane. Moreover, this flooring is beneficial in manufacturing facilities because it is durable and easy to clean. In addition, epoxy flooring is customizable to meet the specific needs of a manufacturing facility, making it a versatile and effective flooring solution.

Still, one disadvantage is that epoxy flooring can be slippery when wet, which can be a safety hazard. Another disadvantage is that epoxy flooring can be difficult to repair if it becomes damaged. However, it is a very durable material that can last for years. Overall, epoxy is a beneficial choice for manufacturing facilities.

Polyaspartic Flooring

When it comes to flooring for a manufacturing facility, there are many options. However, due to its benefits, polyaspartic flooring is increasingly becoming the preferred choice for many facilities.

First, polyaspartic floors are extremely durable and can withstand heavy traffic and equipment. In addition, they are easy to clean and maintain, and they resist staining and fading. Moreover, polyaspartic floors are slip-resistant and fire-resistant, making them a safe option for a manufacturing environment. Finally, polyaspartic floors are quick and simple to install, minimizing downtime in a manufacturing facility.

Consequently, it is not surprising that polyaspartic flooring is gaining popularity in the manufacturing sector.

EMC Coatings Has the Best Concrete Solutions

Home and business owners know that when it comes to updating or repairing their concrete surfaces, they need a company they can trust. EMC Concrete Coatings has been providing quality concrete solutions for years, and we’re here to help with whatever you need. From coatings to repairs and everything in between, we have the experience and expertise to get the job done right.

Our coating services include commercial epoxy coatings, epoxy garage floors, patio coatings, pool deck coatings, and shop floor coatings. In addition, we service the areas of Boerne, Buda, Canyon Lake, New Braunfels, and San Antonio, Texas.

Get a Free Quote Today!

If you’re in need of concrete solutions for your home or business, look no further than EMC Concrete Coatings. We offer a wide range of services that will meet your needs and exceed your expectations. From coatings to repairs, we have you covered.