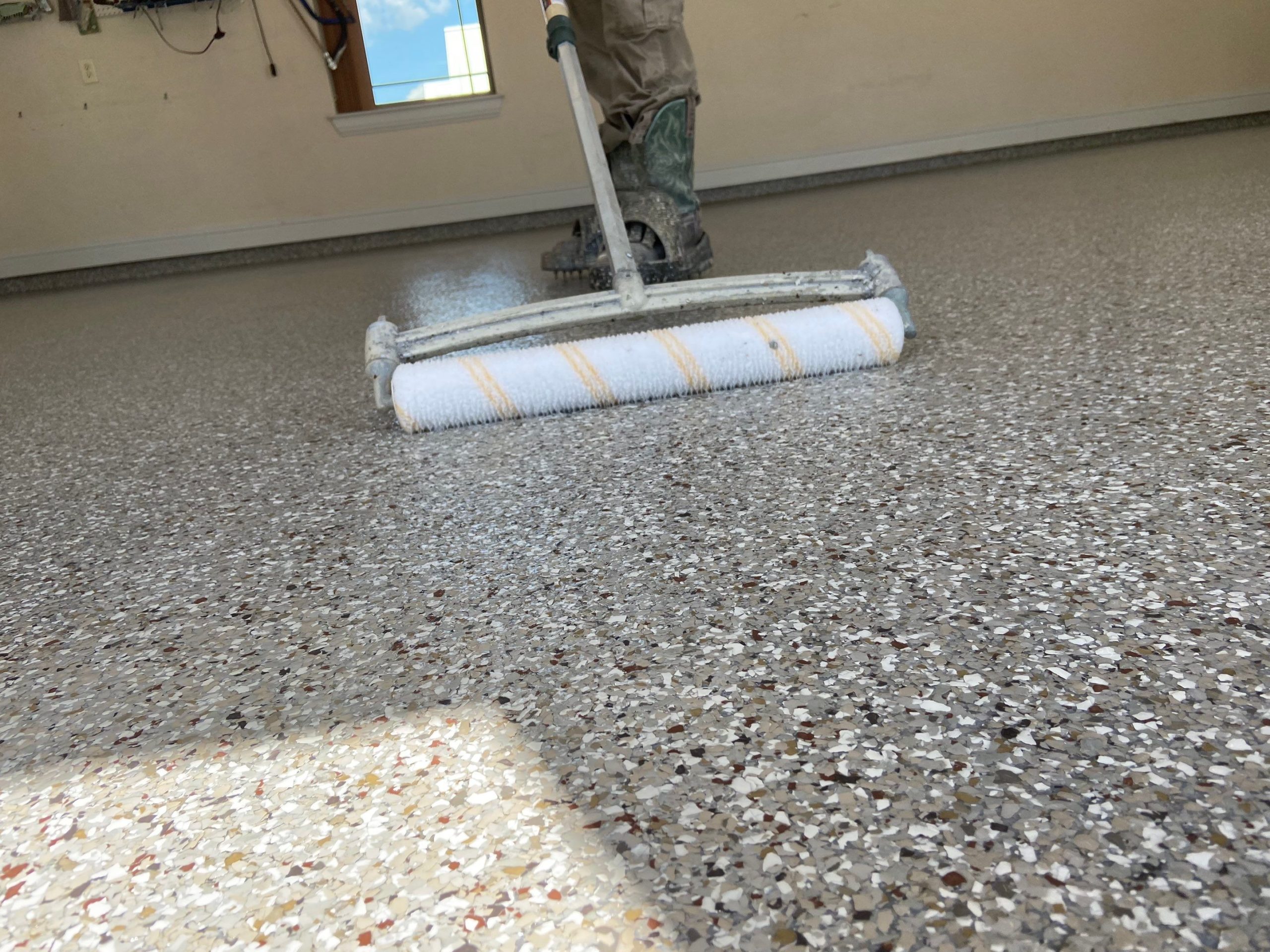

With quality epoxy and an established plan, it is possible to apply an epoxy coating in cold weather. The benefits of slip-resistant epoxy flooring are well-established and can drastically improve a concrete floor with proper application.

Working with epoxy in the cold is doable but requires special care. Read on to learn more about applying an epoxy floor in lower temperatures from our epoxy professionals at EMC Concrete Coatings.

Why Is It More Difficult to Apply Epoxy in Cold Weather?

Applying epoxy floor systems during the winter can be a challenge. Epoxy resin relies on temperature and works most effectively when applied to floors that are over 55 degrees Fahrenheit. The temperature matters because epoxy hardens through an exothermic reaction. Warmer temperatures accelerate the chemical reaction that sets epoxy, but the cold slows or stops this process.

Concrete is typically colder than the air above it and will immediately lower the epoxy’s temperature to match. Taking away the heat takes away the energy needed for the chemical reaction.

This chemical reaction makes epoxy appropriate as a durable garage floor coating but complicates working with the resin in the colder months. When the air and concrete are too low in temperature, the epoxy takes longer or may not harden at all. The bonds created during the chemical reaction are weakened, threatening the overall flooring system and lowering its durability.

How to Apply Epoxy in Cold Weather

Understanding why it is challenging to lay epoxy floors during the winter is crucial to understanding how to combat the cold. Epoxy is useable in winter if a professional takes specific steps to ensure its effectiveness. You can take certain measures to appropriately apply epoxy resin to concrete, providing a durable, attractive coating for your workspace.

For best results, warm up your workspace with the following:

- Propane heaters

- Warming blankets

- Heat guns

- Water bath to warm the liquid epoxy

Use electrical heating appliances for the best results. If you use gas heating, you are introducing outside chemicals to your epoxy environment, which may affect the chemical reaction.

The first step to practical winter epoxy work is heating the surrounding air, but that alone is not enough. The concrete must also be warm, or the epoxy will lose its temperature. Warming both is the most effective.

Maintain an environment of at least 55 degrees for optimal hardening. Control over humidity levels in the room is equally important, as water can affect the epoxy’s adhesion. Applying a vapor barrier to the concrete can prevent water vapor from entering your workspace. Run moisture tests and ascertain the level of humidity before using the epoxy. Keep the moisture level below 85% for best results.

Benefits of Polyaspartic over Epoxy

While creating the optimal environment is crucial to applying epoxy flooring, each brand and type of epoxy is different. Thoroughly examine all instructions for your epoxy, and do as written. Not following the rules will result in damages to your property.

The epoxy may never harden, harden unevenly, or pool in places giving you an uneven floor. It will take longer and potentially cost more during cold weather. You can mitigate those risks by hiring an experienced team to do your epoxy work.

Work with an alternative material if it’s difficult or impossible to warm the environment. You can polish concrete flooring systems during the winter. You can use a polyaspartic topcoat instead of epoxy since its curing time is shorter. It works in temperatures as low as 15 degrees.

If You Want Epoxy Floors, Contact EMC Concrete Coatings

Working with epoxy in the cold requires special care. In over ten years in business, our epoxy experts at EMC Concrete Coatings have done it all. If you still have questions, reach out to us, and we will help you through the process.

EMC Concrete Coatings can help you install an epoxy floor during winter. We also offer polyaspartic top coats that are quick and easy to apply even in cold weather. With our quick-cure materials, we can deliver quality coatings in one day.

When you hire us, we put our decades of experience to work. Laying an epoxy floor is more challenging during the colder seasons, but it is doable with a specialized team and the right equipment.

You don’t have to wait till spring for the floor you want. Our owner-operated business works with epoxy, polyurea base coats, and polyaspartic top coats to ensure that you get the best floor coat for your needs, regardless of the weather. Call us today at (210) 430-4181 to schedule a free epoxy flooring consultation.